Ready-to-install Panels is poised to revolutionise building construction, taking it to a whole new level. They are sandwich panels, made of two Fibre Reinforced Cement facing sheets, on either side of a lightweight concrete core. The core is made from a mix of Portland cement, binders, and silicaceous and micaceous material aggregate.

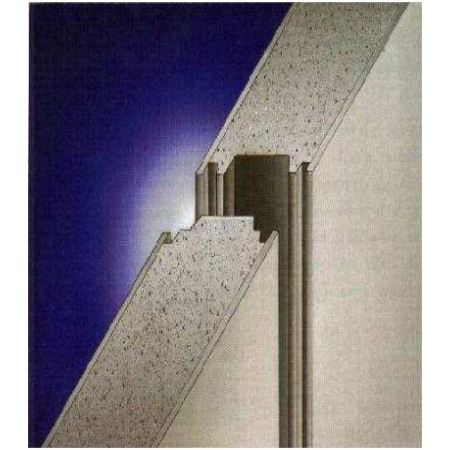

Apart from being fully cured at the factory itself, panels have a tongue and groove jointing system that facilitates rapid construction with minimum effort.

Light-weight, Water-resistant, Fire-resistant, Termite-resistant, Strong and Durable, Sound Insulation, Space Saving, Eco-friendly.

Dry Wall Panels is an ideal solution for drywalls and partitions. This innovative green product, certified by the IGBC and GRIHA, stems from our commitment to creating greener buildings, for a greener planet.

BENEFITS

Lightweight

Allows easy handlings & erections at larger heights. Due to light in weight, the dead load on the structure reduces & hence we can save on the cost of the structure

Water-resistant

Aerocon Panels are having excellent Water resistance properties.

Termite-resistant

Aerocon Panels are having excellent Termite resistance properties.

Space Saving

Due to its slim thickness, it provides additional usable floor space /carpet area compared to conventional walls.

Save Cost

Light-weight, therefore results in structural savings up to 20%

Save Labour

Pre-cured and ready-to-use therefore eliminates on-site curing

Strong and Durable

Aerocon Panels are manufactured from high-quality materials imparting adequate strength & long life. Cement-based products are as good as other conventional materials.

Fire-resistant

Aerocon Panels are having excellent Fire resistance properties.

Sound and thermal Insulation

Aerated panels provide high sound & thermal insulation properties.

Eco-friendly

Usage of recyclable material- Eco Friendly & one of the Green Building materials.

Save Time

10- 20 times faster to construct.

Reusable & Relocatable

Complete structure can be dismantled, relocatable & re-constructed, thus saving money

Aerocon Panels

-

A sandwich panel of two fiber-reinforced cement sheets enclosing a lightweight concrete core composed of Portland cement and Fly-ash

-

Fully cured at the factory, they are ready for installation right away

Tongue and Groove

-

Unique “Tongue and Groove” jointing system facilitates rapid construction with minimum effort

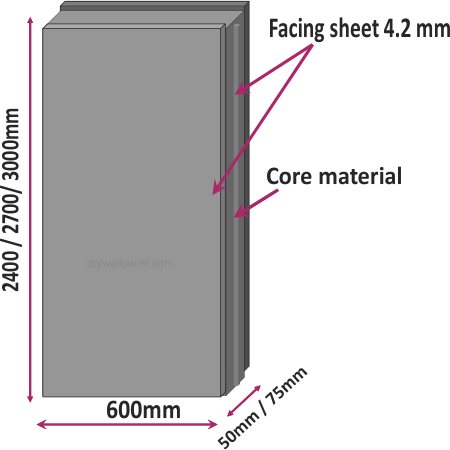

Dimension

Standard width

- Aerocon Panels are available in a standard width of 600mm

Varying Thicknesses

- 50 and 75mm

Lengths

- 2400, 2700, 3000mm

Application Areas

Partition

- Full Height Partition

- Half Height

- Free Standing

Prefab Structures

Roofing

Mezzanine flooring

| Technical Specifications | ||||

|---|---|---|---|---|

| PROPERTIES | UNIT | THICKNESS | REMARKS | |

| 50mm | 75mm | |||

| Nominal Weight | Kg/m2 | 42 | 58 | - |

| Apparent Density | Kg/m3 | 840 | 780 | IS:2380 Part 3 |

| Axial Compression Load/meter width | KN/m | 79 | 90 | Factor of safety–2.5 |

| Bending test (4 point UDL) uniformly distributed load 2.9m span |

Kg/m2 | 55 | 70 | Factor of safety–2.5 |

| Flexural strength/modulus of rupture | Kg/cm2 | 50 | 40 | Typical test results |

| Thermal Conductivity | W/m0K | 0.18 | 0.17 | IS:3346 |

| Sound Transmission Coefficient (Test results of Prasar Bharati and National Physical Laboratories) |

db | 38 | 40 | IS:9901(PartIII)–1981 IS:11050(PartI)–1981 |

| Fire Rating As per test results of CBRI, Roorkie. |

Minutes | 105 | 120 | BS:476 Part 20 & 22 |

| Surface Spread of Flame | - | Class I | BS:476 Part 7 - 1971 | |

| Fire Propagation Index (I) | - | 3 | BS:476 Part 6 - 1981 | |

| Ignitability | - | Class P (Not Easily Ignitable) |

BS:476 Part 5 - 1968 | |

| Note: The above specifications are based on typical test results of Birla Aerocon Panels with Non - Asbestos Fibre Cement Board (conforming IS 14862 : 2000 (Type A)), and are subject to revision. Mechanical properties will vary due to change in moisture content in Panels. *As per test results of CBRI, Roorkee. |

||||

Versatile Applications

School

Office

Mall

Restaurant

Residential Building

Commercial Building

Defence

Industrial Complex

Warehouse

Features and benefits

Savings

- Cost: Light-weight, therefore results in structural savings up to 20%

- Time: 10-20 times faster to construct

- Labour: Pre-cured and ready-to-use, therefore eliminates on-site curing

Space

- Thinner walls: Provides additional carpet area, up to 5%

Strength

- Long-lasting: Cement-based panels

- High axial compression and bending strength: Can build load-bearing structures

Sustainable

- Save resources: Cement and sand are not required

- Reusable: The unique tongue & groove joint makes it easy to uninstall

- Eco-friendly: Use of fly ash

Safe

- Fire: Highly resistant

- Weather: Can withstand adverse conditions

- Termite and water-resistant: Doesn’t permit the growth of bacteria and fungus

- Toxic emissions: None

Tile Adhesives and Grout

Tile Adhesives and Grout Waterproofing

Waterproofing

Reviews

There are no reviews yet.