Meghalite Autoclaved Aerated Concrete (AAC) blocks also known as Light Weight Fly Ash Blocks. It is a lightweight, precast building material that simultaneously provides structure, insulation, and fire and mold resistance.

Meghalite AAC Blocks ( Autoclaved Aerated Concrete - " AAC ") a unique and excellent type of building material due to their superheat, fire, and sound resistance, Maghalite AAC blocks are lightweight and offer ultimate workability, flexibility, and durability. AAC has excellent thermal insulation and acoustic absorption properties. AAC is fire and pest resistant, and is economically and environmentally superior to the more traditional structural building materials such as concrete, wood, brick, and stone.

Aerated Light Weight concrete is today recognized the world over as an environment-friendly product due to its superior insulating and energy-saving properties. Increased use of Maghalite helps to conserve and protect our planet's forest cover.

The Autoclave Aerated Concrete Block, or more popularly, AAC Block is a happening, smart, and green building material now widely used all over India. Made by a Bengaluru based company that's always on the lookout for contemporary innovations in building materials, Meghalite AAC Block has emerged as the most preferred substitute and is fast replacing conventional Red Clay Bricks, CC Blocks, Fly Ash Bricks, CLC Bricks, and so on, which were used in building walls in residential, commercial and institutional construction until now.

A modern solution for better construction, Megalite AAC Blocks comprise 60 - 65% Fly Ash (by weight), with other elements being OPC Cement, Quicklime, Aluminum powder, and Gypsum. With such strong composition, no wonder Meghalite AAC Blocks are highly robust and durable despite their lightweight. Also, this AAC Block’s solidity owes its origins to the calcium silicate and from the process of curing in a pressurized steam chamber called an Autoclave.

Advantages of AAC Blocks

Lightweight

AAC density is less than one-third of that of normal concrete blocks, making it easily handled.

Thermal Comfort

AAC is excellent thermal insulation properties result in improved comfort level and saves heating and cooling costs.

Eco-friendly

AAC to help reduce at least 30% of environmental waste, decrease 50% of greenhouse radiation

Impact Resistant

Wall erected using 100 mm thick are to withstand impact loads potentially resulting from rough usage.

Faster Construction

Speed and ease of installation compared to traditional masonry construction

Sound Resistant

AAC blocks can provide very good sound insulation / sound absorption with an STC rating of 44.

Fire Resistant

More superior than traditional masonry for products with fire resistant up to 4 hours for a nominal block thickness of 100 mm.

Cost-effective

Speed and ease of installation result in cost savings compared to traditional masonry construction

Durable

Histories of usage dated more than 50 years protecting building and remain durable even under extreme weather conditions.

Dimensional Accuracy

Blocks using modern machineries resulting in products with tighter dimensional tolerances.

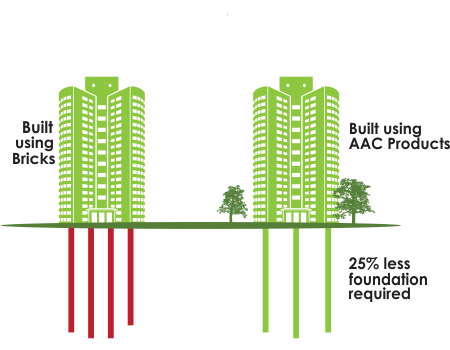

Save on Foundation Cost

Save up to 25% of Foundation Cost

Great savings in foundation and structural costs due to decrease in overall dead load. Due to light weight and low density, overall dead load reduces, thus saving structural steel consumption compared to conventional masonry.

Thermal Control

Thermal Control

Heat insulation 6 times superior than brick. Due to the numerous micropores in AAC, it has a very low thermal conductivity and makes an excellent thermal insulation material. It keeps interiors cooler in summer and warmer in winters.

| Technical Specification | |||

| Property | Units | AAC Block | |

|---|---|---|---|

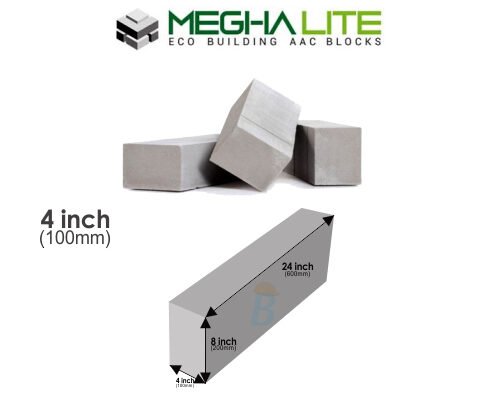

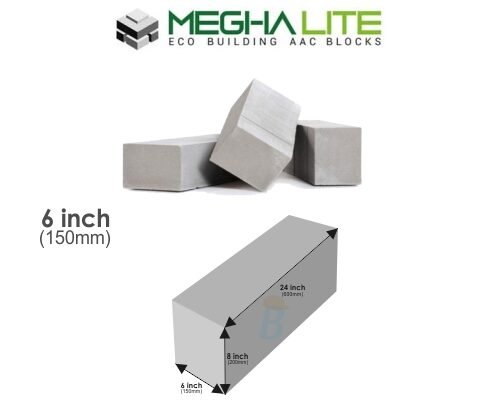

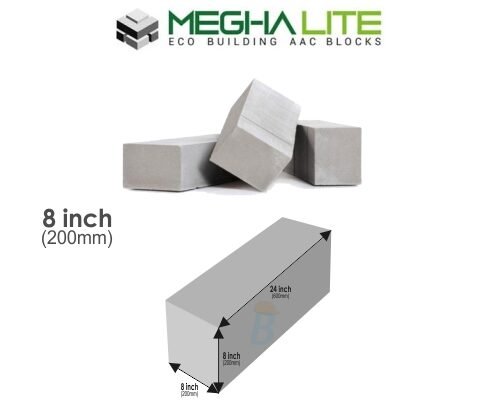

| Size | mm | 600 X 200 X (100 to 250) | |

| Compressive Strength | N/mm2 | Min 4 * | |

| Normal Dry (Oven Dry) Density | Kg/m3 | 551 to 650 | |

| Thermal Conductivity "K" | W/m-k | 0.162 (avg) | |

| Drying Shrinkage | % | 0.1% | |

| Fire Resistance | Hrs. | 2 to 6(Depending on thickness) | |

| Sound Reduction Index | Db | 45 for 200 mm thick wall | |

| Design Gross Density | Kg/m3 | 790 ( appx.) | |

| * As per IS 2185 Part 3 | |||